Methanol has been largely overlooked in the biofuels debate, perhaps that is because that is because it is typically produced from coal and natural gas and is often considered a fossil fuel product. But it is more accurate to think of methanol as a synthetic fuel that can be produced from all manner of carbon based feedstock including carbon dioxide (CO2). Methanol is the simplest and cheapest synthetic fuel molecule and is known as wood alcohol because it was produced from biomass for centuries. Modern production techniques now allow us to directly utilize CO2 captured from industry in the production of methanol to create fuels that have reduced fossil carbon content, zero fossil carbon content, and plastics that offer permanent carbon sequestration.

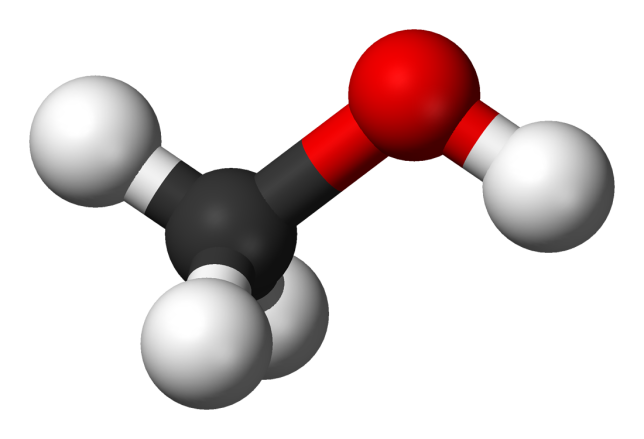

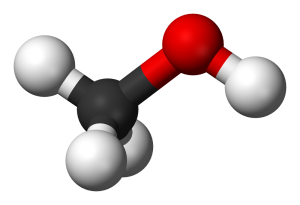

Methanol is simply methane plus one oxygen atom. Methane is CH4 and methanol is CH4O (or more accurately, CH3OH). Methanol occurs naturally in the environment, but commercial quantities have always been produced synthetically using a wide variety of feedstocks, primarily coal and natural gas, but also wood. One of the most productive pathways is to react methane with carbon dioxide to form methanol. In other words, take the two greenhouse gasses that are of the most concern for climate change and react them together to form a stable liquid that can fuel all energy sectors, heat, power and transportation, while also providing feedstock for plastics and chemicals.

When natural gas (methane) is used to produce methanol it is usually reacted with steam (H2O), but this process creates an excess of hydrogen (CH4 + H2O -> CH4O + H2) that is typically used for process heat. If an inexpensive source of CO2 is available it can be included in the reaction to absorb the excess hydrogen boosting yields and productivity of the overall process. Reacting carbon dioxide with methane to form methanol is already an existing commercial process.

Another pathway for producing renewable methanol (biomethanol) from carbon dioxide uses electrolysis of H2O with CO2 (CO2 + H2O + power -> CH3OH). The first commercial plant using this process was built in Iceland in 2011 by Carbon Recycling International and uses CO2 captured from a nearby power plant and geothermal energy for inexpensive electricity to drive the process. This process works well but requires a lot of heat and power and access to inexpensive renewable energy to be environmentally and commercially viable. Research is moving forward to make methanol with CO2 captured directly from the air.

Another emerging option for renewable methanol is to use biogas as a feedstock. Biogas is produced from natural anaerobic digestion of organic materials in dedicated digesters, wastewater treatment plants and landfills. Biogas is roughly a 60%-40% blend of methane and carbon dioxide which makes it an ideal feedstock for biomethanol production.

Currently the biogas industry has been focused on producing electric power or renewable natural gas products (pipeline gas, CNG, LNG). But the biogas industry has been challenged by poor economics for power production as well as spotty access to gas pipelines. Methanol is beginning to gain attention as a third option for biogas producers.

Methanol is a traditional auto fuel with wide usage in race cars and is blended with gasoline in much of the world. But methanol is also widely used as a feedstock in the chemicals industry where it is turned into plastics and a variety of other products. When biomethanol is used to produce plastics it offers a pathway for permanent carbon sequestration.

In 2006, Nobel Prize winner George Olah and co-authors G.K. Surya Prakash and Alain Goeppert published a book titled “Beyond Oil and Gas: The Methanol Economy” where they detailed a vision for renewable methanol replacing traditional fossil fuels for energy storage, transportation and power generation as well as for use as a feedstock for chemicals and plastics. In principal, methanol can serve as a feedstock for the entire spectrum of synthetic hydrocarbon products. Dr.’s Olah and Prakash direct the Loker Hydrocarbon Research Institute at the University of Southern California where they are actively developing novel techniques to recycle carbon dioxide into methanol as well as developing methanol fuel cells.

Compared to gasoline methanol is lower energy density but higher in octane allowing higher compression and more efficient engines with very clean emissions. Methanol is considered to be safer than gasoline and was the preferred fuel in IndyCar racing for decades due to improved safety over gasoline. A dramatic crash at the 1964 Indianapolis 500 led to the switch to methanol after some gasoline fueled race cars caught fire creating a thick cloud of black smoke that blocked the view of oncoming cars leading to additional crashes. One of the cars that caught fire was running on methanol and the fire was noticeably smaller without the heavy smoke and this encouraged race officials to mandate methanol as the standard fuel until 2007 when it was replaced by corn ethanol. Methanol actually burns so clean it is virtually invisible under bright sunlight which is good for the environment but represents a safety concern for firefighters. The use of additives or methanol fuel blends can address the invisible fire concern.

Methanol has been validated by Siemens and GE as a high quality fuel for gas turbines and suitable for electric power production. Methanol can also be used in fuel cells with advantages over hydrogen due to the ease of storage (hydrogen is stored in expensive tanks under high pressure). Methanol has been positively evaluated as a marine fuel to potentially replace traditional dirty bunker fuels that have been banned from the US and Europe. Methanol can be converted into gasoline using the ExxonMobil MTG process (methanol to gasoline).

DME, Dimethyl Ether, is a simple derivative of methanol that serves as a replacement for both diesel and propane. DME stores like propane in simple steel tanks under slight pressure and be directly blended with propane and LPG as a cooking and heating gas and is widely used in China. But DME can also fuel heavy duty diesel engines with only slight modifications to the fuel system. DME is non-toxic and non-corrosive and can be safely handled. Volvo and Mack Trucks are champions of DME in heavy trucking due to its excellent engine performance and extremely clean emissions. DME has very interesting chemistry, it is CH3OCH3, and the two carbon atoms are not bound to each other which means that when DME is burned no soot is produced. DME is one of the cleanest vehicle fuels available and in heavy trucks it would allow for the elimination of the diesel particulate filters that are an expensive annoyance to truck owners and mechanics.

The traditional criticisms of methanol are that it is caustic and toxic to humans, but as a practical matter it is no more toxic than gasoline. Methanol is also corrosive to certain materials, but flex-fuel vehicles that can tolerate ethanol can generally tolerate methanol as well, and we have been designing vehicles for decades that run on methanol so the engineering issues are well understood. Methanol is a huge international industry today and is transported via container ships, rail cars, and trucks and distributed down to the retail level. This broad infrastructure and experience with methanol are strengths that can be leveraged to grow the industry.

Methanol is historically cheap and the commodity pricing today is under $1 a gallon without any kind of subsidies or mandates. The methanol lobby is fairly limited, largely because the industry is pretty successful on its merits without requiring government support. Typically it is the industries that are least economic on their own that lobby the hardest for public support.

But biomethanol does require some public support and policy is needed. Methanol could readily be blended with gasoline but currently it is not allowed in the US. The DME market is also restricted for lack of policy, standards need to be introduced for propane blending as well for the technical specifications for tanks and distribution equipment. DME was just recently legalized as a transport fuel in California. Biomethanol is not included under the renewable fuels standard and there is no way to earn valuable RINs except when biomethanol is used for producing biodiesel which does allow for fractional RIN’s to go to the biomethanol producer. BioDME can earn RINs in California but currently there are almost no DME trucks on the road.

Small scale methanol production technology has greatly improved in recent years and we now have the option to take the two greenhouse gasses that are of the most concern for global warming, methane and carbon dioxide, and react them together to form methanol, a liquid fuel that can provide energy storage and fuel all energy sectors while replacing fossil fuels for the production of chemicals, plastics and synthetics. When biomethanol is used to produce plastics and building materials it offers permanent carbon sequestration.

We are overdue for a serious policy discussion on biomethanol and the central role it can play in a clean energy economy.