Power-to-Gas (PtG) enables the natural gas pipeline network to be used for energy storage, resolving many of the integration issues that plague intermittent renewable energy sources such as wind and solar.

It is well known that finding a solution for scalable energy storage is critical in the pursuit of achieving a renewable energy future. While batteries, pumped-hydro, flywheels and other technologies have their merits, none are able to offer seasonal deep storage at the terawatt scale. Power-to-Gas is an elegant innovation that simply takes excess renewable electricity to create renewable hydrogen and methane for injection into natural gas pipelines or use in transportation. Existing gas pipelines can store hundreds of terawatt hours of carbon neutral methane for indefinite periods of time.

Germany has been pursuing the most aggressive renewable energy targets in the world under their Energiewende program. The Germans have been experiencing challenges in integrating large proportions of wind and solar power into the electric grid because the times of power production do not correlate with times of demand, so there are sunny afternoons when solar PV is outproducing demand, and likewise windy nights when power production must either be curtailed or else exported to neighboring countries at low prices. Adding to the technical challenge is the fact that wind and solar production can spike and drop off very quickly with little warning creating inefficiencies as grid managers scramble to match supply with demand.

Many technology pathways are being pursued towards the goal of broad based energy storage to help meet the challenge of integrating renewables into the power grid. Batteries and flywheels are excellent for rapid discharge and frequency management but are not suitable for long term storage. Pumped Hydro and Compress Air Energy Storage (CAES) offer longer term storage but are fundamentally limited by the requirement of favorable geographies. Chemical conversion of electricity to gas allows the existing natural gas pipeline infrastructure to be leveraged for massive volume, long-term, distributed storage that is cost competitive with other storage technologies. Additionally, the synthetic methane of hydrogen produced via PtG can be utilized as the carbon neutral transportation fuels or elsewhere in industry.

Germany has embraced PtG as a critical component in the Energiewende program. PtG enables German utility operators to manage the gas and power networks in tandem, shifting gas to power and power back to gas as needed throughout the day to match supply and demand. There are 30 PtG plants at various levels of commercial production throughout Germany and neighboring countries.

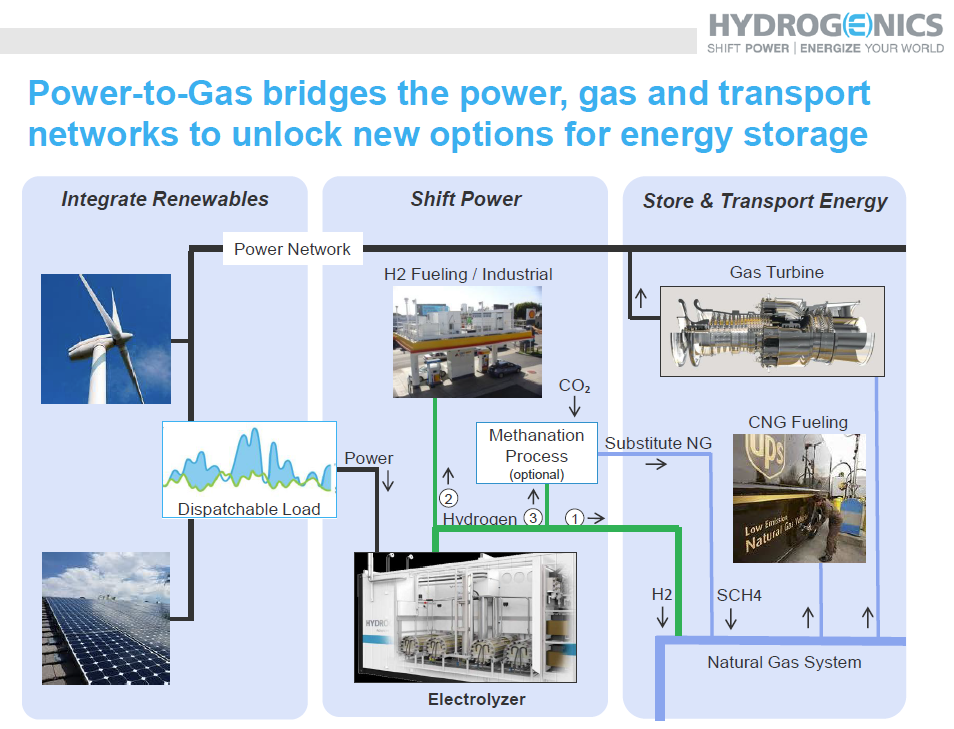

There is a suite of technologies being deployed to create PtG and technology innovation is rapid in the space. PtG begins with basic electrolysis, using electricity to split water, H2O, into its components hydrogen and oxygen. The oxygen has commercial value and is sold or utilized and the hydrogen can be deployed in three different ways.

Hydrogen can be injected directly into the natural gas pipelines and analysis is ongoing to determine what proportions of hydrogen can be supported. Originally it was thought that no more than 5% hydrogen could be used, but depending on the pipeline engineering and downstream uses ratios up to 12% have been achieved. Older cast iron and steel pipes don’t contain hydrogen well because they are embrittled by the hydrogen which can also leak through seams because it is much smaller than a methane molecule. Modern plastic pipes contain the hydrogen much more effectively and can take higher ratios but users must be consulted to ensure their operations are not impacted by higher hydrogen ratios. This is an ongoing area of investigation and pipeline standards for direct hydrogen injection have not been established in Germany.

The second method for hydrogen use is methanation, reacting the hydrogen with carbon dioxide to created synthetic methane, or renewable natural gas. Natural gas is primarily methane, CH4, and synthetic methane is identical to fossil methane and can be blended or substituted with no limitations. The chemical process is known as the Sabatier reaction and is the inverse of methane stream reforming commonly used to produce industrial hydrogen from natural gas.

Methanation of CO2 is one of the many ways to utilize captured carbon dioxide for beneficial purposes and is not limited to use with excess renewable electricity, any energy source could be used including nuclear power. It is entirely feasible that a dedicated nuclear power plant could be set up to do reverse combustion and convert CO2 and H2O into synthetic methane or synthetic liquid fuels that are ultra-pure and carbon neutral, but that is a discussion for a separate article.

The third method for utilizing PtG would be use in transportation instead of pipeline injection. Compressed hydrogen, CNG, or LNG could be manufactured on site for direct use in vehicles as carbon neutral clean fuels.

Two of the leading vendors of P2G solutions are Hydrogenics and ETOGAS. Hydrogenics has over 60 years’ experience manufacturing alkaline electrolyzers and is actively involved in numerous PtG projects in a number of countries. The technical challenge in using older generations of alkaline electrolysis has been the slow ramp up rate from a cold start which limits the flexibility and efficiency for grid integration. Newer generations of hardware have been designed that reduce cold start times from minutes to seconds and Hydrogenics is actively pursuing the market for grid frequency regulation that requires second-by-second reaction response times.

In 2013 ETOGAS inaugurated the world’s largest commercial PtG methanation plant in Werlte, Germany which was built in partnership with Audi and Siemens to produce synthetic natural gas. Audi markets the gas as e-gas and it is distributed via pipeline to CNG filling stations where it is sold as carbon neutral vehicular fuel.

The Werlte plant was constructed next to a biogas digester facility that provides the CO2 for methanation. Since methanation is an exothermic process producing significant heat (approximately 300° C steam), the heat at the Wertle plant is sent back to the digester to facilitate the digestion process. The thermal energy from the methanation is valuable for industrial processes and creates many opportunities for systems integration with other processes. The Wertle plant has an electrical capacity of 6 MW and consumes 2,800 metric tons of CO2 to produce 1000 metric tons of renewable natural gas per year. Though the Wertle plant is the largest commercial PtG plant in operation globally, it is still considered a demonstration plant.

There are a number of emerging PtG technologies coming along including Proton Exchange Membrane (PEM) electrolysis and biological methanation. Biological methanation uses bacteria to react the CO2 and hydrogen into methane instead of traditional catalytic methods, but these processes are still pre-commercial. PEM electrolysis is considered very promising, though not as mature as alkaline electrolysis. PEM is essentially a hydrogen fuel cell in reverse and consumes electricity to produce hydrogen rather than consume hydrogen to produce electricity. The advantage of PEM electrolysis is very rapid response times and expected cost reductions that couple with the development of hydrogen fuel cells for vehicles.

System efficiencies and costs for PtG vary widely on a case by case basis and are closely tied to overall systems integration, particularly in the case of CO2 methanation. Under the best circumstances the life-cycle efficiencies are over 70%, but there are many methods for capturing CO2, many methods for utilizing industrial heat, and many methods for consuming methane, all of which impact full systems efficiency. And while synthetic natural gas is more expensive than fossil natural gas in the American market, SNG from PtG is entirely carbon neutral, which means that it can carry a price premium and earn credits under potential carbon emissions regimes. More importantly though, PtG offers the ability to decouple renewable electricity production from electricity demand and open up alternative industrial and transportation markets for renewable energy.

Despite the interest in Europe, there has been very little discussion of PtG in North America. American environmentalists seem to be so busy fighting hydrofracking and natural gas infrastructure that they are overlooking the incredible promise of renewable natural gas and PtG. There is one project going forward in Ontario, Canada, a 2.5 MW grid storage project by Hydrogenics. News of this project got the attention of the California power authorities (Cal ISO) who just recently signed a contract with NREL (National Renewable Energy Lab) to model the Western States Grid to identify PtG opportunities. California has some of the most aggressive renewable energy targets after Germany and California authorities have come to recognize the potential for using PtG to help integrate renewables into the grid.

Published in Breaking Energy, Dec. 2 (.pdf).