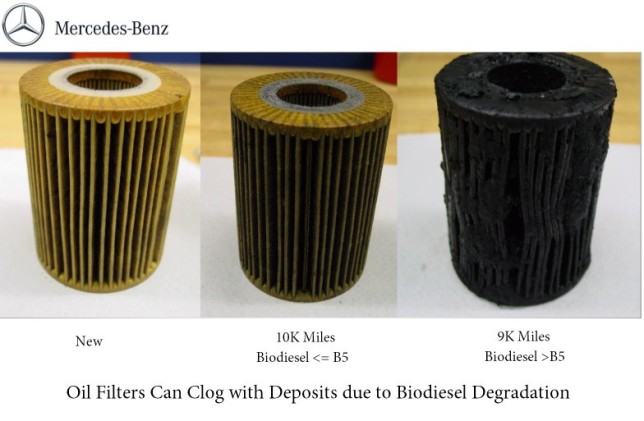

Fuel stability woes challenge the increase of FAME (Fatty Acid Methyl Ester) biodiesel beyond the current B5, or 5% blend. Mercedes-Benz and some other engine OEM’s will not warranty their engines when blends of B6 or higher are used. The reason is due to poor oxidation stability that causes the fuel to biodegrade over time. This process is amplified due to improper storage and handling along the retail fuel distribution chain. Fuels that are in spec at the time of blending have shown degradations in quality as they move out through the retailers. The results of oxidation can include bacterial growth in gas tanks and sludging of engines, fuel injectors and fuel filters.

FAME biodiesel is the most popular type of alternative diesel fuel available today. FAME biodiesel is produced through transesterification of fats with methanol, the fats are obtained from vegetable oils or other fatty acids such as animal fats or waste cooking oils. Biodiesel is hydroscopic, meaning that it attracts moisture and once moisture sets in it can hydrolyze and form a variety of organic acids and bacteria. The main problem with FAME biodiesel is low oxidative stability meaning that it does not store well over time relative to petroleum diesel leading to the buildup of acids and sediments. Factors affecting oxidative stability include the degree of saturation of the feedstock, level of natural antioxidants, carbon chain length and the presence of glycerides.

While all engine manufacturers support the use of B5, they offering varying opinions on blends of B6-B20 and B100. FAME biodiesel is not supported in aviation, even in the use of shared pipelines and storage tanks which can allow cross contamination of fuel. Engine manufacturers such as Audi/Volkswagen, BMW, Mercedes-Benz, Kenworth and Peterbuilt will only warranty B5. In regions where higher blends are on the market and limited consumer choice is available some manufacturers have said they will honor warranties on a case-by-case basis as long as additional maintenance routines are carried out such as increased frequency of oil changes. Other OEM’s such as Freightliner and Case specify warranties based on engine model.

The differences in warranties between the OEM’s lies in the engineering of the engines themselves. Technical variables such as the specifics of fuel injection and oil pan size can make one engine friendlier to higher biodiesel blends than another. Biodiesel has a tendency to collect in the oil pan as sludge and cause oil levels to rise, and depending on the size of the oil pan can cause problems. Other problems include fouled fuel filters, fuel pumps and oil filters.

In the case of Mercedes-Benz, their advanced BlueTEC diesel engines inject some fuel on the exhaust stroke, but since biodiesel has a higher flash point than petroleum diesel the biodiesel does not combust allowing the biodiesel to collect inside the crankcase of the engine itself. This crankcase sludging is irreversible and over time can lead to catastrophic engine failure.

Mandates to increase the blend quantities of biodiesel such as the current proposal in Minnesota to bring all diesel up to B10 run counter to the concerns of engine manufacturers. Biodiesel produced from soybeans, which is more common in the USA than in Europe is particularly problematic. Soybean Methyl Esther has a lower oxidation stability than biodiesel produced from other feedstocks. Yet biodiesel has been a major boon to soybean farmers and they have been a major lobbying force behind raising the blend requirements.

Mandates to increase the blend quantities of biodiesel such as the current proposal in Minnesota to bring all diesel up to B10 run counter to the concerns of engine manufacturers. Biodiesel produced from soybeans, which is more common in the USA than in Europe is particularly problematic. Soybean Methyl Esther has a lower oxidation stability than biodiesel produced from other feedstocks. Yet biodiesel has been a major boon to soybean farmers and they have been a major lobbying force behind raising the blend requirements.

The solution to this problem is improved biodiesel fuel quality and quality monitoring through the supply chain to the point of sale. Many of the quality problems are resulting from improper fuel storage and handling. Oxidation stability is only measured at the time of blending and there has been no dispute over fuel quality at that point. The problems seem to be occurring in distribution and Mercedes reported that as much as 15% of retail biodiesel was out of spec. This is a problem for consumers and the entire industry and needs to be addressed for the industry to grow.

Other alternatives for improving biodiesel are to move beyond FAME to other 2nd Generation formulations such as Hydrotreated Vegetable Oils (HVO) or Biomass to Liquids (BTL) produced through Fischer-Tropsch processes.